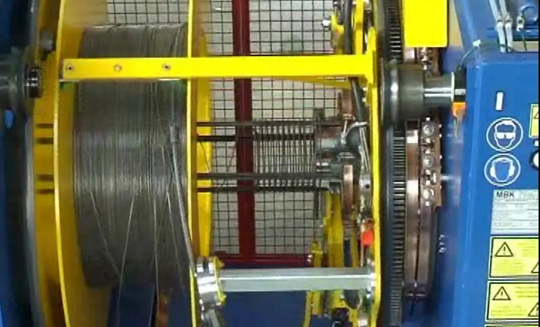

- Pile Cage Welding Machine ABGZ110/230 Model

Square cage welding machine

Tubular roll welding machine

Tubular roll welding machine

Pile cage welding machine

Pipeline reinforce mesh welding machine

- 01. Introduction of pile cage welding machine ABGZ110/230 model

- The pile cage welding machine is used for production of concrete poles.The welding machine is with a speed regulating motor pulls the longitudinal bars and the pile cage welding block makes the welding while the circumferential steel bars wind round the longitudinal bars.The main transformer generates a strong current through the electrode welding block to make the crossed longitudinal and circumferential bars rise quickly in temperature until they become plastic and then the contact points are solidly welded under the pressure of the welding block.The pole welder has such advantages as high efficiency,quick forming,no twisting,high strength,labor and time saving and reduced intensity of labor,etc.

The welder is composed two major parts of mechanical drive and electrical control.

- 02. Product standards

- National standard:Circular Reinforced Concrete Electric Pole(GB396-94)

National standard:Circular Prestressed Electric Pole(GB4623-94)

Main technical specifications:

1.Diameter of the welded pole steel skeleton:tip diameter Φ110~Φ230,taper 1/75

2.Length of the welded pole steel skeleton:7m~15m

3.Number of longitudinal steel bars:8~32

Diameter of longitudinal bars: Φ5~Φ6.5mm, Φ8~Φ11mm

4.Diameter of circumferential bars: Φ3mm, Φ4mm, Φ5mm

5.Main welding transformer:100KVA,self-cooled

6.Main motor:YCT3KW excitation

speed regulation range 125~1250r.p.m.

Material reel motor:YCT2.2KW

Traction speed:30~40mm/s

Main machine speed:15~30r.p.m.

- 03. Technical requirements

- 1.Altitude:no more than 1000m

2.Ambient temperature:within the range of ±40℃

3.Relative air humidity:no greater than 35%

4.To be used in non-explosion-hazardous medium,without enough amount of conductive dust in gas to corrode the metal and electrical insulation.

5.Reliable operation with the power network voltage within ±10% of the rated voltage