- 200 Square Cage Welding Machine

200 square cage welding machine

200 square wire cage welding machine

Square concrete pile wire cage welding machine

Construction reinforcing square cage welding machine

Square concrete pile wire cage welding machine

- 01. Introduction of 200 square cage welding machine

- This machine is the production of high strength concrete pile reinforced skeleton of special welding machine. This machine has a large weldable main rebar diameter, advocate muscle strength loss small, long skeleton, does not distort, the machine performance is good, the cage body pitch can be arbitrary regulation, forming fast, stable performance, easy operation and maintenance, etc. Recently, in order to adapt to market requirement, our company create a new generation of human-machine dialogue control system, to automatic differentiation weld square pile vertex Angle steel, select famous brand electrical components, operating more simple, convenient, complete a key. Concerned expert thinks: the machine design is novel, in such aspects as design, quality, degree of automation are the domestic first and won the national utility model patent.

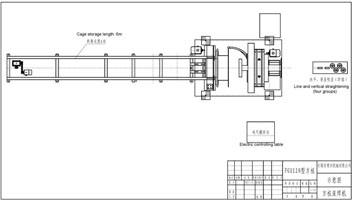

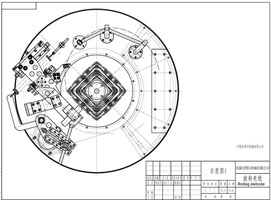

- 02. Construction introduction

- Steel skeleton automatic forming method:

Longitudinal bar follow axle direction guide, welding device and hooped tray rotate around axle direction and welding institution flex follow cage body radial automatically. Set according to the pitch and length of the cage body automatic welding forming.

Welder partition:

Mechanical traction pneumatic bracket parts; Host welding and feeding part; Jin tail holder frame part; Special electrical control cabinet of four parts.

- 03. Main technical parameter

- 1. Diameter of welding skeleton is φ200-φ450.

2. Length of welding steel skeleton is 1-15mm (on special condition it can be longer).

3. Longitudinal bar number is 4 or 8(according to customer’s requirements).

4. Longitudinal reinforcement diameter: ⊄5-12

5. Ring reinforcement diameter: ⊄4-⊄6.

6. Cage body pitch is 2-120mm and adjustable.

7. Driving power is 9KW.

8. Welding power is 200KVA.

9. Rotational speed of the main engine≤40rpm.

10. Welding meaner electric resistance welding

11. Welding material Carbon content less than 0.20% of the reinforcement

12. Welding joint strength loss Less than or equal to 5%

13. Welding joint shear force More than or equal to 200kg

14. Welding transformer type of cooling Self cooling

15. Welding power 380V±5% 50HZ

16. Environment temperature -5°C-﹢35°C

17. Relative temperature Less than 85%

18. Total weight of welder around 9T-15T

- 04. Main elements material list

-

ItemNameType and specificationPlace of production1Motor protectorPKZMC-16Moeller2Frequency changerATV31 seriesSchneider3PLCCPU224XPSiemens4Human-machine interfaceTD-400CSiemens5Turn on/off powerS8JC-15024Omron